DSXH43GA1WW General Electric Dryer - Overview

Sections of the DSXH43GA1WW

[Viewing 5 of 5]Keep searches simple, eg. "belt" or "pump".

Lower Front Felt Seal w/Adhesive

PartSelect #: PS832645

Manufacturer #: 5303937183

The lower front felt seal with adhesive, also known as a drum felt seal, is used in dyers and allows the drum to easily glide on the front panel. For this repair project, you will need the following t...

$28.95

In Stock

Dryer Timer Knob

PartSelect #: PS264401

Manufacturer #: WE01X10082

This knob accepts a D-shaped shaft.

$68.55

In Stock

Rear Bearing

PartSelect #: PS267858

Manufacturer #: WE3X70

Bearing Only. This part helps your appliance run as quietly as possible.

No Longer Available

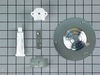

Rear Bearing Kit

PartSelect #: PS267556

Manufacturer #: WE25X10001

This kit comes with the rear bearing, shaft support, lubricant and other items required for the installation.

$118.29

In Stock

Drum Glide

PartSelect #: PS755802

Manufacturer #: WE03X10007

Sold individually. There are some dryers that require 2 per dryer. They attach to the outer-most sides of the bearing.

$65.29

In Stock

Rotary Knob

PartSelect #: PS264402

Manufacturer #: WE01X10083

Sold Individually. This knob takes a D-shaped shaft.

No Longer Available

Rear Bearing Shaft Support

PartSelect #: PS265828

Manufacturer #: WE13X10011

Introducing the GE Dryer Drum Bearing! This genuine replacement part is the ultimate solution for enhancing your dryer's performance. It is ideal for supporting the drum as it spins, offering stabilit...

$97.96

In Stock

DRYER BEARING BRACKET

PartSelect #: PS12710145

Manufacturer #: WE13X28680

This bracket is used on the drum bearing.

$45.95

In Stock

Handle

PartSelect #: PS264332

Manufacturer #: WE01X10013

Screws are not included. Handle only.

No Longer Available

Upper Felt Seal with Adhesive

PartSelect #: PS652857

Manufacturer #: WE09X10013

Experience smooth operation with this genuine Dryer Felt Seal from GE. This product is designed to allow your dryer drum to glide effortlessly on the front panel, promising a quieter, more efficient p...

No Longer Available

Questions And Answers for DSXH43GA1WW

Be the first to ask our experts a question about this model!

✖

Ask a Question

Ask our experts a question on this model and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Common Symptoms of the DSXH43GA1WW

[Viewing 2 of 2]Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Loud rhythmic squeaking

About a year ago I had to replace the front sliders. I had thought at the time that I should replace the belt and check the rear bearing, but I was in a hurry, and the wash was backing up, so I didn't do it. Oops. Within 6 months dryer started squeaking. Did I get around to pulling it out, and greasing rear bearing. Nope. Dbl oops.

... Read more

r />

Luckily on this model, everything is pretty basic, strong, and well made. The rear bearing after 9 years of constant use (5 person family)had simply run out of grease, and then worn into the plastic housing that holds the rear bearing. NOTE TO ALL -- probably too late if you're reading this -- but just grease your rear bearing by using a grease gun with high temp grease (car bearing grease works fine)through the small hole at back of dryer dead center of drum. It will take 5 min, and probably prevent the need for this repair, or delay it substantially.

Unplug dryer, turn off gas, and disconnect gas hose and duct hose. Inspect the latter two and consider repacing while you're at it. Move dryer to where you can get at front and back without cursing too much.

So...take a putty knife, and put a little masking tape around the blade if you're worried about scratching the finish on your dryer. If you're doing this repair, your dryer is probably at least as old as mine, and you can skip the tape and just bear with some small scratches.

Slide the putty knife into the groove between lid and front of dryer and pop up. (held by spring clips)

Now tip up lid and slide back, you may have to wrestle it a bit, or it may come off like a charm. Put it out of the way.

Take a sec to look at the interior wiring (you unplugged the dryer, right?) If you see any worn or raw spots, take some electrical tape and fix. Should be fine though. Take a vacuum and suck up any extraneous lint, dirt etc.

Tip dryer up slightly and block with wood or a brick. There are two screws at bottom -- undo these. IF they're missing, no worries, they're not critical. Put dryer back down.

Get a trouble light or a good lamp and shine ti wher you can see interior of dryer. There are two screws, one on each side on the INSIDE of the dryer, connecting the side panels to the front. Undo those. Put them in a little baggie and mark them "interior fr screws." I know, you're thinking "I can just remember them." But trust me, this way, you can't lose them or screw up. Now use the putty knife to pop the front panel off the sides. Do this gently, and don't yank the front way back, as the drum will drop. Oh, on mine there was a yellow plastic doohicky in the middle at top. Take that off too (one tiny screw) put the screw back in part way and stick the doohicky in the baggie.

OK, so the front panel should now be loose. It is still on a couple of little tabs at the bottom, which you prefer not to bend. So lift the front slightly and then back it out, while you (or preferably a helper) holds the drum so you can let it down gently. The front is attached to all sorts of wiring. You don't need to disconnect ANYTHING. THe front should be able to be moved away to the right like a door. Rest this up against something so as to not strain the wiring. On the front of the door are the felt and plastic sliders. If they look beat up or worn, replace them now -- or like me, you can do the job twice... That part is super simple...

Now, got back of dryer, there is a vent at back bottom. Remove three (or less) screws) and remove little door. Probably substantial lint here. Vacuum like crazy. The belt comes down around the drive pulley, and then up and over the idler pulley (to keep tension on belt. IF this feels loose/easy to move, replace the belt. In fact, if the belt is over 5 years old, replace the belt. (or when it breaks, you get to open everything again). Just unhook the spring and the idler will be loose and you can remove the belt off the pulleys -- it's now just around the drum. Slide the idler pulley off the stem

Luckily on this model, everything is pretty basic, strong, and well made. The rear bearing after 9 years of constant use (5 person family)had simply run out of grease, and then worn into the plastic housing that holds the rear bearing. NOTE TO ALL -- probably too late if you're reading this -- but just grease your rear bearing by using a grease gun with high temp grease (car bearing grease works fine)through the small hole at back of dryer dead center of drum. It will take 5 min, and probably prevent the need for this repair, or delay it substantially.

Unplug dryer, turn off gas, and disconnect gas hose and duct hose. Inspect the latter two and consider repacing while you're at it. Move dryer to where you can get at front and back without cursing too much.

So...take a putty knife, and put a little masking tape around the blade if you're worried about scratching the finish on your dryer. If you're doing this repair, your dryer is probably at least as old as mine, and you can skip the tape and just bear with some small scratches.

Slide the putty knife into the groove between lid and front of dryer and pop up. (held by spring clips)

Now tip up lid and slide back, you may have to wrestle it a bit, or it may come off like a charm. Put it out of the way.

Take a sec to look at the interior wiring (you unplugged the dryer, right?) If you see any worn or raw spots, take some electrical tape and fix. Should be fine though. Take a vacuum and suck up any extraneous lint, dirt etc.

Tip dryer up slightly and block with wood or a brick. There are two screws at bottom -- undo these. IF they're missing, no worries, they're not critical. Put dryer back down.

Get a trouble light or a good lamp and shine ti wher you can see interior of dryer. There are two screws, one on each side on the INSIDE of the dryer, connecting the side panels to the front. Undo those. Put them in a little baggie and mark them "interior fr screws." I know, you're thinking "I can just remember them." But trust me, this way, you can't lose them or screw up. Now use the putty knife to pop the front panel off the sides. Do this gently, and don't yank the front way back, as the drum will drop. Oh, on mine there was a yellow plastic doohicky in the middle at top. Take that off too (one tiny screw) put the screw back in part way and stick the doohicky in the baggie.

OK, so the front panel should now be loose. It is still on a couple of little tabs at the bottom, which you prefer not to bend. So lift the front slightly and then back it out, while you (or preferably a helper) holds the drum so you can let it down gently. The front is attached to all sorts of wiring. You don't need to disconnect ANYTHING. THe front should be able to be moved away to the right like a door. Rest this up against something so as to not strain the wiring. On the front of the door are the felt and plastic sliders. If they look beat up or worn, replace them now -- or like me, you can do the job twice... That part is super simple...

Now, got back of dryer, there is a vent at back bottom. Remove three (or less) screws) and remove little door. Probably substantial lint here. Vacuum like crazy. The belt comes down around the drive pulley, and then up and over the idler pulley (to keep tension on belt. IF this feels loose/easy to move, replace the belt. In fact, if the belt is over 5 years old, replace the belt. (or when it breaks, you get to open everything again). Just unhook the spring and the idler will be loose and you can remove the belt off the pulleys -- it's now just around the drum. Slide the idler pulley off the stem

Read less

Parts Used:

-

Mark from San Diego, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

46 of 57 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud screeching noises from the rear of the dryer whenever in was running.

We unlatched the top of the dryer by pushing a screwdriver under the two areas where there were metal clips holding it down. We then removed the yellow clip screwed onto the top frame. We removed the front frame of the dryer by unscrewing the two screws holding the front frame on--one on either side. We didn't undo the wiring to the con

... Read more

trols, we just kind of pivoted the front aside. We pulled the drum out from the plastic holder attached to the back of the dryer frame also unwinding the belt encircling the drum. Then we unscrewed the 3 screws holding the bearing to the back of the drum. We removed the plastic that had held the bearing by undoing the screws to the back of the frame. We installed the new bearing by screwing it to the back of the drum with 3 screws. We installed the plastic holder to the back of the frame by 2 screws and put the little ball bearing in. We used the grease that came with the kit to grease up the plastic where it held the big bearing attached to the back of the drum and inserted the drum back into the body of the dryer frame, pushing the bearing into the plastic holder. The hard part was getting the belt back around the drum and through the pulley on the motor that holds the belt. When that was accomplished, we put the yellow plastic holder back on the front frame with the screws and put the front back on after thoroughly cleaning the inside bottom area where there was a lot of lint. Then we snapped the top back into place.

Read less

Parts Used:

-

Kenneth from Boise, ID

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

11 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Felt around drum holder worn and torn.

1. Removed face of dryer (drum 'holder')

2. Disconnected door switch wires

3. Tore off existing felt

NOTE: The length of the felt that I recieved from PartSelect was incorrect (too short). Since the existing felt was worn and torn at the top, I replaced only a length that matched the length of the new felt.

... Read more >4. Used a razor blade-type gasket remover/scraper to remove the exisitng glue

5. Applied new glue (which comes with the felt) onto the felt and let it set up

NOTE: In hindsite, I would apply the glue to the drum holder instead, as the glue otherwise soaks into the felt. If applied to the drum holder instead, the glue will spread out and provide more surface area for adherence.

6. Installed the new felt, starting at one end and working my way around to the other end, being careful not to stretch it

7. Trimmed the remainder of the existing felt (see first NOTE)

8. Scraped the drum holder below the pulled away ends of the exisitng felt

9. Applied glue to the existing felt, including the trrimmed ends so that the ends do not pull away from the ends of the new felt

10. Re-attached the existing felt

11. Let the glue set-up overnight

12. Reinstalled the face of the dryer, turning the drum so that the felt will not get pushed away

13. Reconnected the door switch wires

14. Turned dryer on, with lid still raised, to check for any drifting of the felt

15. Once assured that the felt would stay in place, put the dryer in service

NOTE: I replaced the felt becasue of the gap that opened due to compression of the felt. The gap, as well as a torn piece of the felt that entered the interior of the drum, was catching clothes and tearing them as they were rotated between the drum and the drum holder. The new felt eliminated this problem.

2. Disconnected door switch wires

3. Tore off existing felt

NOTE: The length of the felt that I recieved from PartSelect was incorrect (too short). Since the existing felt was worn and torn at the top, I replaced only a length that matched the length of the new felt.

... Read more >4. Used a razor blade-type gasket remover/scraper to remove the exisitng glue

5. Applied new glue (which comes with the felt) onto the felt and let it set up

NOTE: In hindsite, I would apply the glue to the drum holder instead, as the glue otherwise soaks into the felt. If applied to the drum holder instead, the glue will spread out and provide more surface area for adherence.

6. Installed the new felt, starting at one end and working my way around to the other end, being careful not to stretch it

7. Trimmed the remainder of the existing felt (see first NOTE)

8. Scraped the drum holder below the pulled away ends of the exisitng felt

9. Applied glue to the existing felt, including the trrimmed ends so that the ends do not pull away from the ends of the new felt

10. Re-attached the existing felt

11. Let the glue set-up overnight

12. Reinstalled the face of the dryer, turning the drum so that the felt will not get pushed away

13. Reconnected the door switch wires

14. Turned dryer on, with lid still raised, to check for any drifting of the felt

15. Once assured that the felt would stay in place, put the dryer in service

NOTE: I replaced the felt becasue of the gap that opened due to compression of the felt. The gap, as well as a torn piece of the felt that entered the interior of the drum, was catching clothes and tearing them as they were rotated between the drum and the drum holder. The new felt eliminated this problem.

Read less

Parts Used:

-

Robert from York, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!