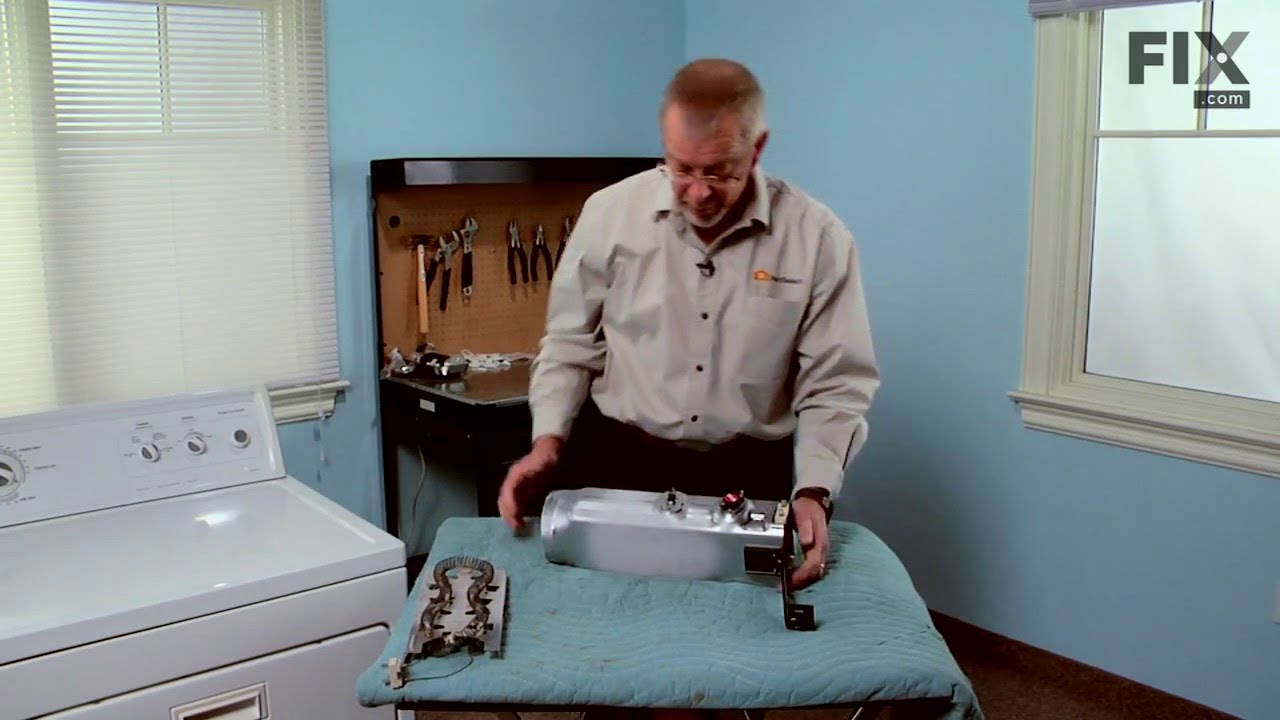

MEDB855DC4 Maytag Dryer - Overview

Sections of the MEDB855DC4

[Viewing 6 of 6]Keep searches simple, eg. "belt" or "pump".

Dryer Heating Element

PartSelect #: PS11741416

Manufacturer #: WP3387747

When connected to electricity the dryer heating element glows red hot and generates heat. When air is blown over it, it heats the air which is used to dry the clothes. The heating element fits inside ...

$56.11

In Stock

Dryer Repair Kit

PartSelect #: PS373088

Manufacturer #: 4392067

The Whirlpool Dryer Repair Kit is a universal maintenance kit for 27-inch dryers, compatible with various models from Whirlpool, Kenmore, Maytag, and others. It includes a belt, drum rollers, an idler...

$37.75

In Stock

Dryer Idler Pulley

PartSelect #: PS334244

Manufacturer #: 279640

This Idler Pulley includes the tri-ring and gasket and everything included here is manufacturer-certified. This part maintains correct tension on the drive belt in order to spin the drum properly. If ...

$25.95

In Stock

Dryer Drum Support Roller

PartSelect #: PS11752609

Manufacturer #: WPW10314173

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. This part is sold separ...

$18.88

In Stock

Dryer Thermostat Internal bias

PartSelect #: PS11746740

Manufacturer #: WP8577274

The internal-bias thermistor (Thermistor, Dryer Thermister, Dryer Thermistor) prevents the dryer from overheating by monitoring and controlling the temperature of the inside of the dryer drum. It is l...

$35.67

In Stock

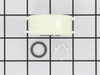

Dryer Tri Ring

PartSelect #: PS11755850

Manufacturer #: WPW10512946

If you notice that your dryer is noisy or will not tumble, you may need to replace the tri ring. This part is triangular, and is less than an inch in size. Tri rings can be found both on the idler pul...

$10.95

In Stock

Washer Leveling Foot

PartSelect #: PS1609293

Manufacturer #: 49621

If your washer shakes or vibrates loudly when it reaches its max speed, check that the leveling legs are even. To ensure that the washer is firmly on the ground using all four legs, adjust the legs so...

$7.29

In Stock

Idler Pulley w/Bracket

PartSelect #: PS11726337

Manufacturer #: W10837240

The idler pulley with bracket ensures proper tension on the dryer’s drive belt, allowing the drum to spin effectively. This assembly includes the pulley and arm, making it ideal for replacing a worn o...

$27.24

In Stock

Dryer Heating Element Wire Kit

PartSelect #: PS334206

Manufacturer #: 279457

This kit is used for electric clothes dryers, and it comes with a yellow wire nut.

$9.95

In Stock

Dryer Screw

PartSelect #: PS11746840

Manufacturer #: WP90767

This screw is sold individually.

$7.95

In Stock

Dryer Screw 1016 X 1

PartSelect #: PS11741409

Manufacturer #: WP3387230

This screw is sold individually.

$8.37

In Stock

Questions And Answers for MEDB855DC4

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Sort by:

- < Prev

- 1

- 2

- Next >

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Rose

February 2, 2020

Our dryer is only 6 months old and the af light keeps coming on while the dyer is running.

For model number MEDB855DC4

Hello Rose, thank you for your question. An AF (Restricted Air Flow) error code indicates that the lint screen or vent is clogged; the vent may be crushed, kinked or have too many turns in it going from the dryer to the outside vent. We would recommend checking the lint filter, and venting tube to be sure there are no restrictions. I hope this helps.

1 person found this helpful.

Was this helpful?

Thank you for voting!

Jose

March 31, 2022

Que año es este número de modelo de secadora eléctrica maytag? Porfabor

What year is this maytag electric dryer model number? Please

For model number MEDB855DC4

Hello Jose, thank you for your question. The dryer was manufactured in 2017. We hope this helps.

Hola José, gracias por tu pregunta. La secadora se fabricó en 2017. Esperamos que esto ayude.

Was this helpful?

Thank you for voting!

Ted

January 22, 2023

When rotating selector knob mode lights randomly jump around. Unable to select a specific function. When jiggling selector knob mode lights also jump around.

For model number MEDB855DC4

Hello Ted, thank you for writing. Your issue sounds like there may be an electrical issue. The Main Harness is part PS12346174. We have a video on how to use a multimeter to test the wiring. We are pleased to have been able to help.

Was this helpful?

Thank you for voting!

Related Parts:

Keith

July 4, 2023

Wouldn’t dry. Replaced heating element since that tested bad. Fuse and thermostat tested ok. Still won’t dry. What’s next? Can new thermostat kill other parts after tested good or did I miss something else?

For model number MEDB855DC4

Hi Keith, thank you for the question. Since you have tested and replaced some of the most common parts, you may need to check the thermistor, part number PS11746740, which monitors the temperature of the burner or heater housing and will shut off the heat once a sufficient temperature is reached. If the thermistor is faulty, the dryer may not heat at all and you may need to replace this part. We hope this is what you were looking for!

Was this helpful?

Thank you for voting!

Related Parts:

David

November 7, 2024

Dryer not heating. What do I need to take off to test. Do I need to take the the top off or back off first

For model number MEDB855DC4

Hello David, thank you for your inquiry. Check the Heating element PS11741416 as well as the Thermostat, Internal-Bias PS11746740. Both have videos to show how to get in and replace. We hope this helps.

Was this helpful?

Thank you for voting!

Related Parts:

Additional Links:

- < Prev

- 1

- 2

- Next >

Common Symptoms of the MEDB855DC4

[Viewing 10 of 10]Noisy

Fixed by

these parts

these parts

Show All

Not Heating

Fixed by

these parts

these parts

Show All

Door won’t close

Fixed by

these parts

these parts

Show All

Too hot

Fixed by

these parts

these parts

Show All

Drum Not Spinning

Fixed by

these parts

these parts

Show All

Won’t Start

Fixed by

these parts

these parts

Show All

Door Pops Open

Fixed by

these parts

these parts

Show All

Leaking

Fixed by

these parts

these parts

Show All

Touchpad does not respond

Fixed by

these parts

these parts

Show All

Marks left on clothes

Fixed by

these parts

these parts

Show All

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

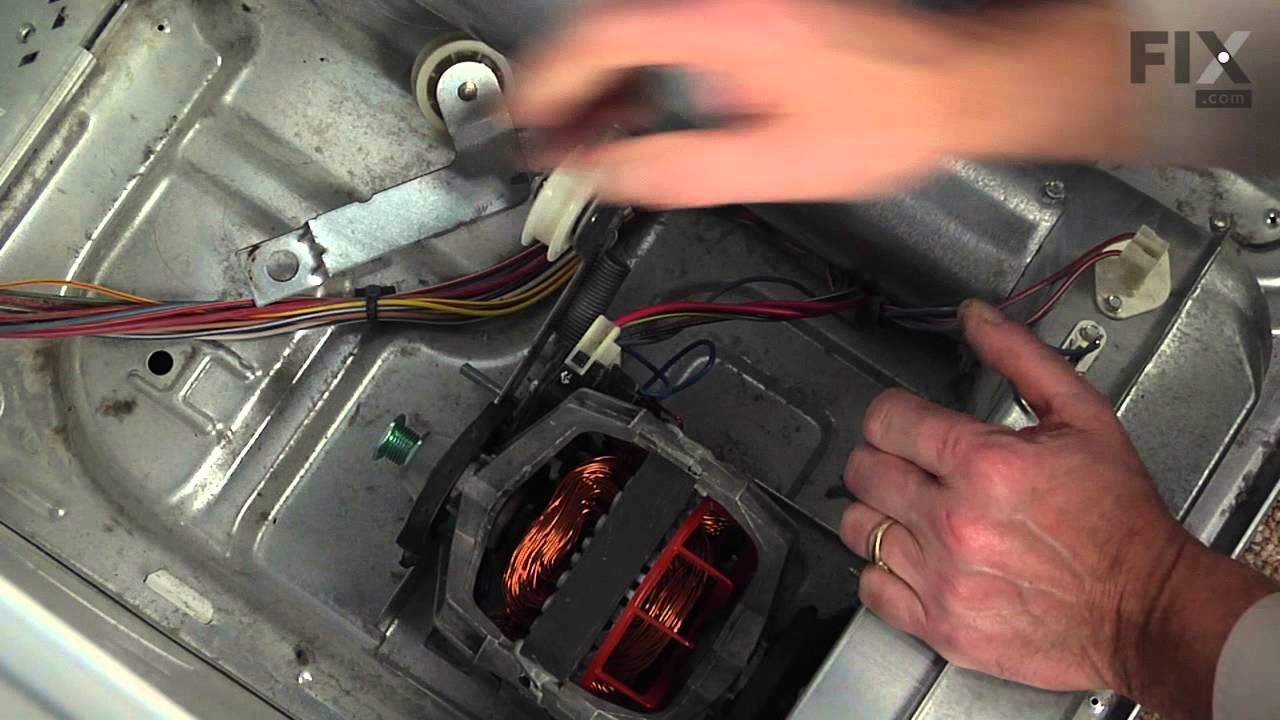

Burned out heater element

Remove the kick plate from the bottom of the dryer by sliding a putty knife along the top edge to release the plastic clamps, one on each side about 4" in from the edges. The kick plate folds out and down. You will see the heat shield on the right, held in by one hex head screw. Remove screw and heat shield. The element is positioned in a

... Read more

n open-front housing and is fastened to the left side of the housing by two hex head screws, located on the "rail" of the element and right near the two wires. Remove the hex-head screws that hold the element in place and disconnected the two wires by pulling them out by hand or with needle nose pliers. The only difficulty here is the cramped working area...I recommend a stubby socket driver for these two screws. Most of this I had to do by feel because I could not see the screw heads. Once the screws are out and the wires have been disconnected, slide the old element straight out toward you. You may need to disconnect a small plastic hose located to the left front of the element, but this hose just pulls right off. Vacume the dust & lint build-up out of the whole area, wipe out the element housing and clean up the whole underside of the dryer prior to installing the new element. Installation is reverse of removal. It also might be a good opportunity to clean out your exhaust duct and the vent to the outside. (Never use the aluminum foil-accordian-type duct.) If the exterior dryer vent has any kind of screen over it, remove it and get rid of it. Screens collect lint, lint builds up and burns out elements.

Read less

Parts Used:

-

Alan from Brooksville, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

510 of 607 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

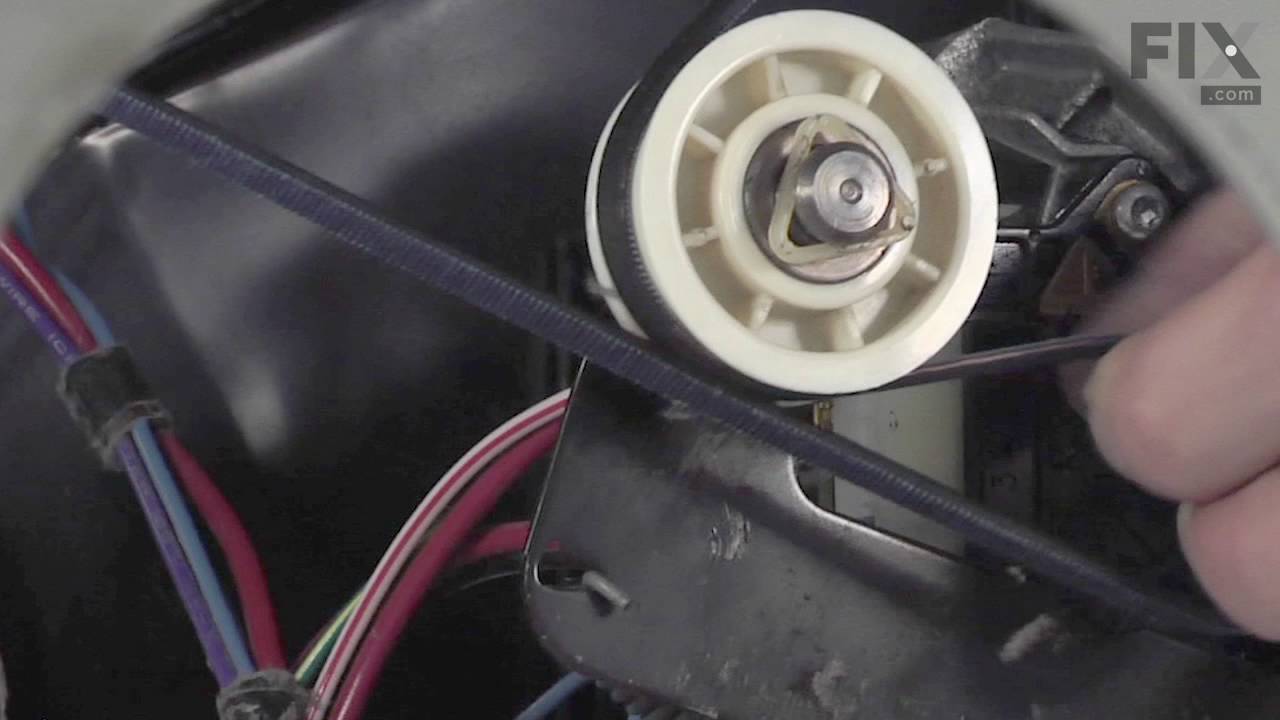

very loud squeeling sound

The issue was the idler pulley. First I began opening up the front panel based on a youtube video but soon realized the model was slightly different and required a lot more items to remove. I saw the pulley in the back with nothing in the way so I put the front panel crap back on and removed the rear panel. There it was, very simple to re

... Read more

move and replace. I'm not looking forward to drum rollers though. Hopefully they're aren't as difficult as they appear.

Read less

Parts Used:

-

jason from HOLDEN, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

94 of 100 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky Dryer Noise

I purchased the dryer repair kit with the drum belt, wheels and idler pulley. I watched the instructional videos online and it seemed fairly straight forward. Breaking down the dryer and replacing the pulleys was easy enough. My problem began when I tried to feed the drum belt around the idler pulley. After finishing the job, the dryer wo

... Read more

uld not turn and the sensor light stayed on. I thought something else was broken with the dryer and spent hours trouble shooting other problems that I was having. Finally I figured out that the drum belt was not installed correctly around the idler pulley. However, I could not get it properly installed from the front of the machine so I tried from the rear still with no avail. I finally had to fish the old belt out of the garbage can that I had thrown away earlier. I lined up the old belt with the new one in the kit and discovered that the new belt was much smaller, so I put the old one back on the drum. Here's the lesson I learned...make sure the belts are the same size before attempting to install. The old idler was responsible for the squeaking and that stopped but I am still using the same old drum belt. Hope it lasts.

Read less

Parts Used:

-

Eddie from PELZER, SC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

72 of 79 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!