Parts That Fix Whirlpool Range WFE775H0HZ1 Little to no heat when baking

This is a heating element compatible with various makes of ranges and ovens and is sold as an individual part. Measuring 20.5-inches wide and 20.25-inches (with terminals) long, this heating element is a genuine OEM part. If your range is not heating during the bake setting, not heating evenly, or if the element is burnt out or damaged, the element will need to be replaced. This repair is simple and only requires that you disconnect your oven from the wall outlet and use an appropriate screwdriver to disassemble and replace the element with the additional support brackets to secure it.

Replacing your Whirlpool Range Bake Element

Customer Repair Stories

2. Removed two (2) screws from bottom panel in oven cavity

3. Lifted out bottom panel

4. Removed two (2) screws from bake element standoffs.

5. Removed two (2) screws from bake element (Rear of oven cavity)

6. Removed Terminal Block Cover Box by removing two (2) screws and lifting up on it.

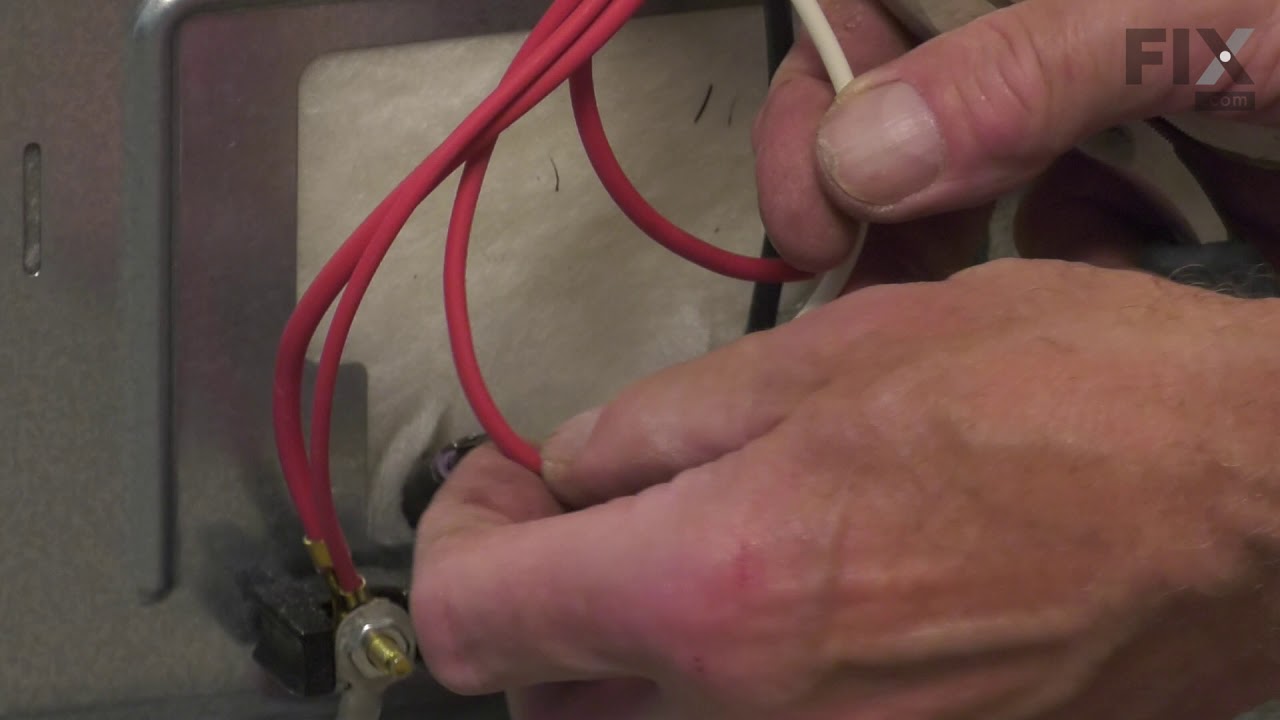

... Read more >7. Removed lugs from the ends of the bake element.

8. Extracted bake element.

9 Inserted bake element through rear opening and attached the two lugs removed in step 7.

10 Inserted two screws removed in step 5.

11. This bake element only had a standoff bracket in the front. Used one (1) screw from step 4. for front standoff.

12 Replaced bottom panel and two screws.

13 Reinstalled Terminal Block Cover Box and two screws.

14. Plugged oven in and tested oven.

-

Bryan from ROME, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

-

Helen from PURVIS, MS

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

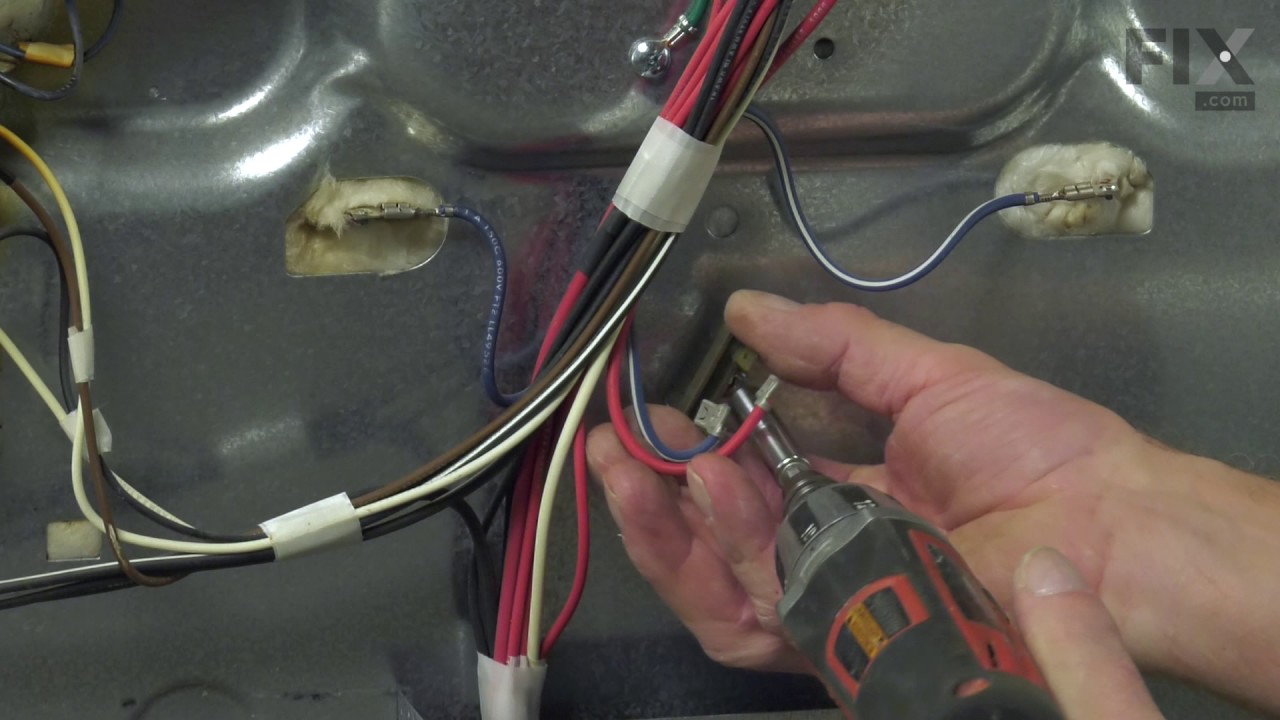

This oven temperature sensor, for ranges, works together with the oven control board to measure and regulate the oven temperature. The sensor detects the temperature in the oven cavity. If the following symptoms occur, replacing the temperature sensor could be the solution: Little or no heat when baking, oven not heating evenly, oven will not start, and/or oven is overheating. Often, if the sensor is defective, the oven temperature will fluctuate and be inaccurate by more than 50 degrees. The tool needed for this replacement is a #2 square head screwdriver or a #2 Philips screwdriver. Remember to unplug the range before installing the part.

Replacing your Whirlpool Range Range Sensor

Customer Repair Stories

-

Hal from Santa Rosa, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

The sensor that has been replaced is not what is expected. After reading all of the instructions for adjusting the temperatures, the only temp that stays steady is when we first turn on the oven to 350 degrees. That stays s ... Read more teady but when I turn it to 400 it slowly goes up to 425 degrees.

-

Ruth from Oregon, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This part is used as a safety feature. If your range overheats this part will shut the range down.

Replacing your Whirlpool Range Range Safety Thermostat

Customer Repair Stories

Works great again...without the light

-

Joseph K from PAHRUMP, NV

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

-

Derek from Houston, TX

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

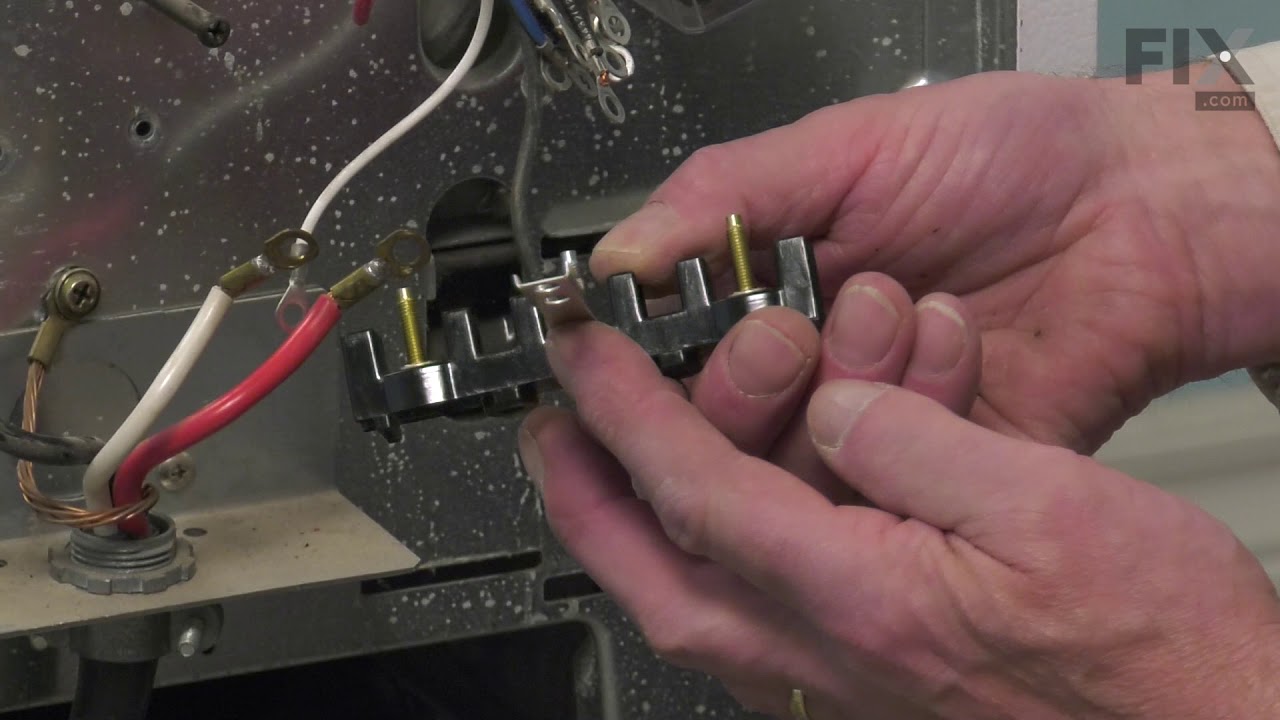

This part is for oven ranges, it connects individual wires and protects the device from electrical surges, voltages, and current. With this part, the house power is connected to the range wire harness. Some symptoms replacing the terminal block could be a solution for are little to no heat when baking, element will not heat and/or it will not start. This part will prevent loosening and will reduce damage caused by corrosion (by two different metals). Refer to the instructional diagram for further replacement guidance and exact placement. You must unplug the appliance before installing this part and wear gloves to protect your hands.

Replacing your Maytag Range Range Terminal Block

Customer Repair Stories

Then I removed the fire panel over the terminal block and the issue was apparent. The nuts on the terminal block were corroded. This had cause the resistance in the connection to raise and burn up the ... Read more wire to my oven plug at the terminal block.

I removed the whole back panel and everything else seemed OK visually.

1. I go new connectors for the oven plug, stripped the wires, and crimped on the new connectors.

2. The terminal block DOES NOT come with the nuts to connect the wire to the terminal block. Mine were so corroded they had to be replaced. So I went and purchased the correct ones and installed the terminal block and reconnected all the wires.

3. I applied some dielectric grease to the connections through out the process of reinstalling to prevent it from happening in the future.

-

Jared from UNION GROVE, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

-

Joseph from Decatur, GA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

This is a multi-use and multi-appliance screw. It can be used on a microwave, refrigerator, range/oven, air conditioner, dehumidifier, washer, or dryer. The measurements of this screw are 8 x 1/2 inch. It has 6 threads. Refer to the manual provided by the manufacturer for further information on repair and accurate guidance. Remember to wear work gloves as a safety precaution.

This broil element is an essential component in ranges, providing the heat needed for broiling at the top of the oven. If the broil function in your oven isn’t working correctly, this part may need replacement. It is a genuine OEM part and is compatible with a range of models. Be sure to check that the part number matches your appliance before placing your order, as even minor differences in size or shape can occur. Before installation, always disconnect electrical power to the range for safety, and wear work gloves to protect your hands during the repair process.

Customer Repair Stories

-

Brady from Loop, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers