MAH3000AGW Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Mashine leak was quickly diagnosed as rip in boot

The machine comes quickest appart with a cordless screwgun and a #2 Phillips.

To unhook the wire with spring it is easiest to use a needle nose plier and make a hook from a coat hanger or use a paint can opener.

Pay attention when yo line up the boot with the flange in the back, that the rectagular protrusions line up with the holes in the flange. You may have to stretch the boot a bit and push it all the way in with a dull tool.

Get someone to help you put the wire back on if you want to do it fast and easy. Otherwise hook it on the spring and get the pliers on the loop on the other side and pull it together, torquing the wire back so that it does not make the boot slip fo the flange.

Done

To unhook the wire with spring it is easiest to use a needle nose plier and make a hook from a coat hanger or use a paint can opener.

Pay attention when yo line up the boot with the flange in the back, that the rectagular protrusions line up with the holes in the flange. You may have to stretch the boot a bit and push it all the way in with a dull tool.

Get someone to help you put the wire back on if you want to do it fast and easy. Otherwise hook it on the spring and get the pliers on the loop on the other side and pull it together, torquing the wire back so that it does not make the boot slip fo the flange.

Done

Parts Used:

-

Daniel from Avon, CT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

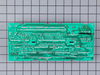

Motor/board , ran erraticly-stopped midstream

Had to move all the concoctions my wife uses on my greasy work clothes [ purple power, dawn dishwash soap,lestoil, etc..] Removed front , removed back panel..Replaced board then motor..Replaced belt while I was in there.I had already changed out the tub bearing assembly earlier..Quite a complex machine when you get in that deep..Runs like new...

Parts Used:

-

Roy from Painesville, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor did not have the ability to rotate washing machine drum.

-

Raymond from Huntington Sta., NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

14 of 30 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One of the drum baffle's boke from it's mount

Removed old broken plastic grommet's and installed two new plastic grommet's. Attached new baffle using old screws. Used a short piece of picture frame wire to install the two new grommets by fishing them into place with out removing the washer drum.

Parts Used:

-

James from Raton, NM

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I found water on the floor beneath the washer. Further inspection revealed the door boot was torn.

I removed the screws around the front door. Then removed the front face. I removed the bolts holding the top down at front top corners. I removed the detergent dispensor. Next I removed the spring and hold down cable. I then pulled out the old boot. I then, with the help of my son, pulled the new boot around the drum. Then attached the cable and spring. Next pushed the boot into the front retainer. I then put the dispenser in and the front back on. Good as new. It was not hard as long as you have someone to help with pushing the boot around.

Parts Used:

-

GREGORY from HALIFAX, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor had an open in winding

1) Removed machine front by removing four (4) screws. 2) Removed rear access panel. 3) Replaced antiquated motor controller with upgade revision; basically unplug and plug 4) replaced motor and 5) closed up unit. Whole job took about an hour with half the time spent moving the unit to work oo.

Parts Used:

-

Robert A. from Warwick, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

8 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replace front and rear bearings and bellows

Of course I looked at you tube to get the instructions on how best to do the job. It was very helpful. Getting the front bearing out was the major issue. It was so corroded that I could not get it out with a hammer and punch. I had to build a bearing puller which I copied from the you tube video out of a 3" schedule 40 pipe. After that the repair went very smoothly. Putting on the bellows cable and spring assembly took two of us. Also putting the clips that held the inside drum on took two of us. One of us used channel loks to squeeze the two drums together while the other installed the clip. I had trouble identifying the tube seal part number. I phoned for help and the customer service person was very helpful and ordered me the correct part. Thank you

Parts Used:

-

Tom from PUYALLUP, WA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer was so loud in the spinning cycle it sounded like a jet was taking off

We took the washer completely apart. Replaced the bearings, pulley and

belt. We decided to replace anything that involved the spinning cycle while we had it all apart.

It was well worth the time and effort we put into it. It works like a chime

and is very quiet . Silence is golden ! Hopefully it will work another 18 years.

belt. We decided to replace anything that involved the spinning cycle while we had it all apart.

It was well worth the time and effort we put into it. It works like a chime

and is very quiet . Silence is golden ! Hopefully it will work another 18 years.

Parts Used:

-

Loanne from W BROOKFIELD, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

loud noise during spin cycle

got instructions off internet from others who did same repair; after taking inner basket out, used drift to remove outer bearing; seal was difficult to remove but used drift to force innner bearing into seal and seal popped out. had help reinstalling inner basket into outer basket.

Parts Used:

-

Brian from Louisville, KY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

7 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water leaking around washer

First ya have to find the problem that takes time.

Pulled the front off via the four screws, two on the door and two on the opp side. Removed the two top hold down brackets that hold the top on (on the front), popped out the four screws for the detergent and the top hinged up, The hose was right there. Removed the two hose clamps, found the crack ordered if from you guys.(very fast) slapped it in and put a load in.

Pulled the front off via the four screws, two on the door and two on the opp side. Removed the two top hold down brackets that hold the top on (on the front), popped out the four screws for the detergent and the top hinged up, The hose was right there. Removed the two hose clamps, found the crack ordered if from you guys.(very fast) slapped it in and put a load in.

Parts Used:

-

Dennis from Bethel, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

seal went out bearings also had to be replaced

Had to remove the tub. Tha bearings had to be removed from the drum. After installing the new bearings(which are available @ O'rReilly's) the seal was't bad

Parts Used:

-

Robin from Wagoner, AL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench set

8 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top Of Dispenser Broke At Hinge

Removed 4 screws holding dispenser frame. Removed old & installed new frame. Top, hinged lid needed to be slightly bowed so hinge pins could be fit in holes. End of repair.

Parts Used:

-

KENNETH from Portsmouth, RI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No cold fill

I checked the internet and downloaded service manual. Diagnostics took me from the cold water valve solenoid through the wiring loom to the control board. Fix was to replace board. The board is located in the control panel at the top of the machine and has a number of wires connected by push on terminals, all the terminals are slightly differant apart from the relay connections so it is difficult to get it wrong, I needed to undo two nuts and the control panel hinged forward, the circuit board is fixed by two nuts. The machine is designed to be repaired from the front if you cannot access the back covers. It means taking the front panel off which is held by four screws and two nuts which is a bit fiddly but easy with a nut driver.

Parts Used:

-

Gary from Chattanooga, TN

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

leaking water at the seal between the drum and door assembly

I took the door off, front panel, soap dispenser(to lift the top out of the way)and took off the cross braces on the front of the machine. I pealed the door bellows off and took the drain hose apart; there was much gunk and debris to clean out...maybe something here was clogged? Removed all the snap clips and took the front of the tub off;the tub seal seemed good, but lots of grime/gunk build up.I cleaned all surfaces, put the new tub seal on,and put it all back togther. The hardest part was working the snap clips back on; I worked a few on both sides, top and bottom, and then filled in the rest. The machine has been working fine for a month now, no leaks:)

Parts Used:

-

max from antioch, IL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

7 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bulb worked for a couple days and has now burned out, filaments dangling

To replace the light bulb, I removed the screw and the cover, unscrewed the old bulb, replaced with the new bulb and replaced the cover, securing it with the small screw. It worked appropriately with normal use for a few days and then I noticed the light was not coming on when I opened the door.

I removed the cover and pulled out the bulb to find that the filaments inside are dangling and burned through. I need them replaced, please.

I removed the cover and pulled out the bulb to find that the filaments inside are dangling and burned through. I need them replaced, please.

Parts Used:

-

Amy from JUNCTION, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!