WTW4880AW1 Whirlpool Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

fabric softener wasn't dispensing

The old part popped right off, and new one installed. Works Great!!!

Parts Used:

-

Carol from MT STERLING, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer -Maytag Centennial- would NOT agitate. It would run through all cycles as indicated by the lights and even spin at the end, but never agitated. It also did not appeared to go into "sensing" mode at the start. Took a long time to move from "sensing" light to "wash" light. Did not hear or see a

There are a number of videos showing how to do this repair:

>Disconnect power and water - cold, hot and drain.

>Put washer on its side on a stand (low platform) to get to the bottom.

Better than than just laying front of washer on floor.

>Used a drop light to help see bottom.

>Removed Pulley Cover using nut driver - has 2 screws with nut

heads.

>Removed and replaced the Shift Actuator (part provided) using a

Phillips screw driver - 2 green screws. Unplugged electrical

connector which should be reconnected before new unit is screwed

back down.

Replacement part is not the same as the original. From what I read.

this part has been a problem with these washers.

>Put Pulley Cover back on.

>Reset washer upright.

>Reconnected water and power.

>Ran "CALIBRATION". In Diagnostic Test Mode, turned to "rinse"

light on and pushed "start" button.

>Ran "AUTOMATIC TEST". In Diagnostic Test Mode, turned to "spin"

light on and pushed "staet" button. Washer agitated in first cycle

- "sensing" and in "wash".

.

Washer has been working as it should and I a very happy with the results.

I must say that PartSelect Identified the bad part as the Shift Actuator right off from the symptoms I provided.

>Disconnect power and water - cold, hot and drain.

>Put washer on its side on a stand (low platform) to get to the bottom.

Better than than just laying front of washer on floor.

>Used a drop light to help see bottom.

>Removed Pulley Cover using nut driver - has 2 screws with nut

heads.

>Removed and replaced the Shift Actuator (part provided) using a

Phillips screw driver - 2 green screws. Unplugged electrical

connector which should be reconnected before new unit is screwed

back down.

Replacement part is not the same as the original. From what I read.

this part has been a problem with these washers.

>Put Pulley Cover back on.

>Reset washer upright.

>Reconnected water and power.

>Ran "CALIBRATION". In Diagnostic Test Mode, turned to "rinse"

light on and pushed "start" button.

>Ran "AUTOMATIC TEST". In Diagnostic Test Mode, turned to "spin"

light on and pushed "staet" button. Washer agitated in first cycle

- "sensing" and in "wash".

.

Washer has been working as it should and I a very happy with the results.

I must say that PartSelect Identified the bad part as the Shift Actuator right off from the symptoms I provided.

Parts Used:

-

Maxwell from RINGWOOD, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer would not spin on wash cycle

My daughter is the handy one in the family. She followed Steve's video installation steps and in an hour i was washing clothes.

Parts Used:

-

Kim from MOUNT UNION, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

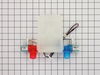

water inlet valve stopped working

used the Parts.com video. I am not mechanical at all, but removed the old part and installed the new part without a hitch. Very happy.

Parts Used:

-

Zoran from ROCKVILLE, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Was it getting education out of the top agitator

I went to a site that helped me diagnose the potential problems with my washer. It was the dogs that had gone bad and we're no longer gripping the upper agitator. Socket set to go in and undo the bulb the holes the upper agitator in place. You just remove the assembly that holds the dogs and I used a new washer that goes in between the upper agitator and the lower agitator. Save beaucoup bucks and it's sort of empowering for a non mechanical person. The website scared me right to you guys. And I also bought another order we can involve the upper agitator and an extra set of those dogs. Awesome company! Customer service is incredible!

Parts Used:

-

John from CASCO, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burning smell, ASSUMED it was the belt

Once we put the washer on it's side noticed lots of oil on the floor and in the belt cover area. Replaced belt anyway but issue is the leaking transmission. Starting warranty process since Maytag carries a 10-year part warranty and machine is 6.5 years old. Wish me luck !!!

Parts Used:

-

James from MAHWAH, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer shaking

the repair went well but I still haven't received a refund for the order was was sent incorrectly. Order #22085769 order date 2/3/23

Parts Used:

-

Oralia from DALLAS, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Worn out agitator directional clogs.

I just ordered the complete agitator kit since I didn't know for sure what I all needed, and it made my repair so easy replacing since it was all complete. I followed video which was a great help. Got it all done in 25 minutes. Very easy. Thank you...

Parts Used:

-

Dee from SNOHOMISH, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My washer was squealing on the spin cycle! Also shaking & moving!

We also purchased from this site the agitator repair kit! The youtube videos were extremely helpful!

Parts Used:

-

Donna from IRON MOUNTAIN, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set, Wrench (Adjustable)

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top agitator did not work

I removed the cover for the softener dispenser on the top of the agitator. Then reached in and removed the cover of the nut and washer which was very sticky and sealed with an o-ring. This took a bit of pressure. Then used a socket wrench with an extension to loosen the bolt and took the whole agitator out of the machine. Then I set the agitator on the floor and with a fine 12 inch long screw driver released the catches while turning and pulling the agitatior with my other hand and holding the lower agitatior on the floor with my feet. I then turned the upper part over and removed the cogs and holding mechanism.

Then I reversed the process after replacing the cogs with the new part. 25 minutes total.

Then I reversed the process after replacing the cogs with the new part. 25 minutes total.

Parts Used:

-

George from Danbury, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator began skipping and not moving through part of turn

Remove dispenser and barrier cap by hand to access cam assembly. Unbolted agitator assembly and pulled up firmly.

Able to access and replace cams. Before pulling out note how assembled and make sure to put back exactly the same. Singe person using this machine for 8 years. Poor design or quality of cams to fail so soon. Family of 5 would have been through this in a few years. For only 15 dollars definitely worthwhile repair. Parts arrived in days.

Able to access and replace cams. Before pulling out note how assembled and make sure to put back exactly the same. Singe person using this machine for 8 years. Poor design or quality of cams to fail so soon. Family of 5 would have been through this in a few years. For only 15 dollars definitely worthwhile repair. Parts arrived in days.

Parts Used:

-

David from Stanton, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator worn

First removed the cap, took out the screw, pulled out old agitator and replaced it with the new one

Parts Used:

-

Marilyn from Heath, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Partial Agitation - CAM Agitator teeth worn

1. Removed the fabric softener dispenser

2. Removed Barrier Seal Cover

3. Removed bolt and seal

4. Removed and replaced CAM Agitator Assembly

5. Reversed the removal steps.

2. Removed Barrier Seal Cover

3. Removed bolt and seal

4. Removed and replaced CAM Agitator Assembly

5. Reversed the removal steps.

Parts Used:

-

Joseph from Jupiter, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the agitator was making loud noises and then the top part stop working

My husband just took the bolt in the middle took the broken one, put the new one, put the bolt back the lid the rubber seal and done. Working like new.

Basically we did what everyone else did with this part, it help me realize I did not need to call a repairman for this, I knew hubby would be able to do this.

Basically we did what everyone else did with this part, it help me realize I did not need to call a repairman for this, I knew hubby would be able to do this.

Parts Used:

-

Lorena from Tampa, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top section of agitator was slipping.

I ordered the new cogs but didn't want to wait the few days for them to arrive. So I decided to try and temporarily repair the old ones. After looking at the picture of the new ones on this site I realized that the teeth were just worn down. I took all four of them out and used a grinding disc to carve the teeth down deeper. They were not perfect. (I would recommend holding the teeth with a vise.) However, after reinstalling the cogs the machine worked perfect and that was two weeks ago. I'm not going to install the new ones until I have to.

Parts Used:

-

Stephen from Hot Springs, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!